Neuralink’s technology builds on decades of BMI research in academic labs, including

several ongoing studies with human participants. The BMI systems used in these studies

have no more than a few hundred electrodes, with connectors that pass through the skin.

Also, their use requires laboratory equipment and personnel. Our challenge is to scale

up the number of electrodes while also building a safe and effective clinical system

that users can take home and operate by themselves. Recent engineering advances in the

field and new technologies developed at Neuralink are paving the way for progress on

each of the key technical hurdles.

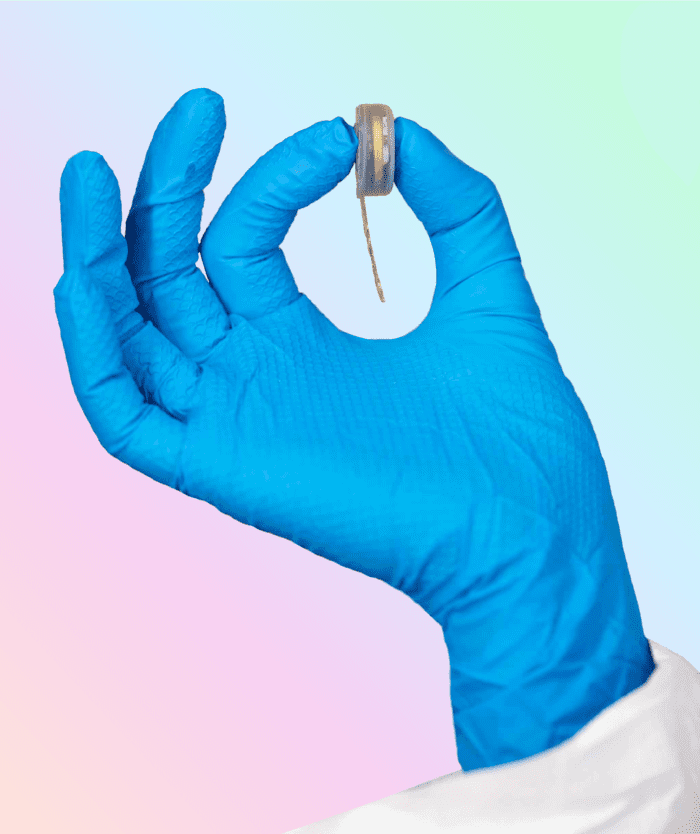

ELECTRODES

In order to optimize the compatibility of our threads with the surrounding tissue, they

should be on the same size scale as neighboring neurons and as flexible as possible.

Therefore, we microfabricate the threads out of thin film metals and polymers. But the

threads also have to resist corrosion from fluid in the tissue, and the electrodes must

have sufficient surface area to allow stimulation. To meet these criteria, we’ve

developed new microfabrication processes and made advances in materials science. These

include the integration of corrosion-resistant adhesion layers to the threads and rough

electrode materials that increase their effective surface area without increasing their

size.

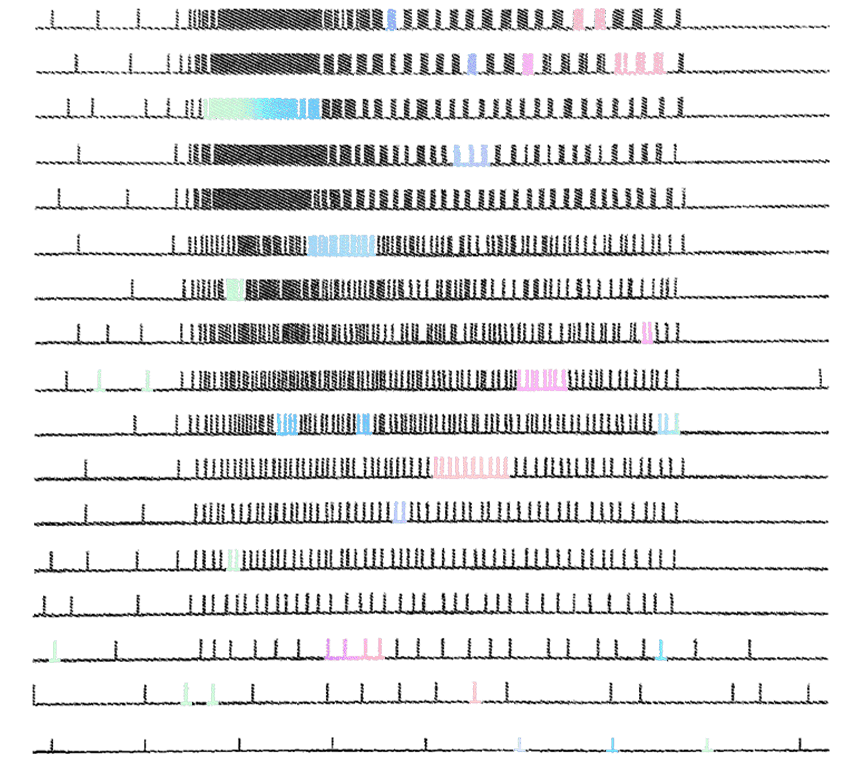

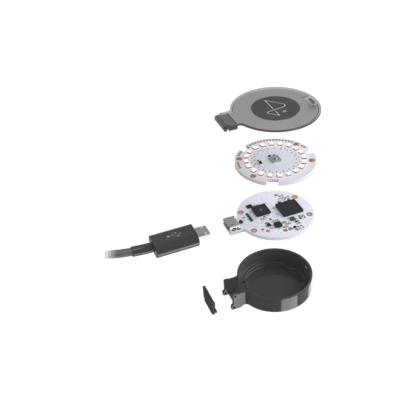

CHIPS

Our Link needs to convert the small electrical signals recorded by each electrode into

real-time neural information. Since the neural signals in the brain are small

(microvolts), Link must have high-performance signal amplifiers and digitizers. Also, as

the number of electrodes increases, these raw digital signals become too much

information to upload with low power devices. So scaling our devices requires on-chip,

real-time identification and characterization of neural spikes. Our custom chips on the

Link meet these goals, while radically reducing per-channel chip size and power

consumption over current technology.

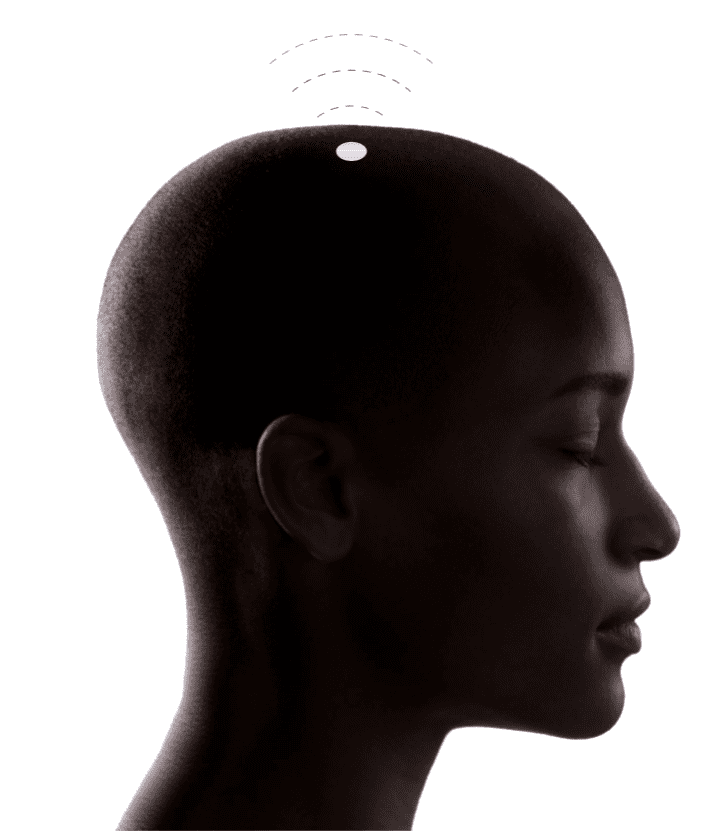

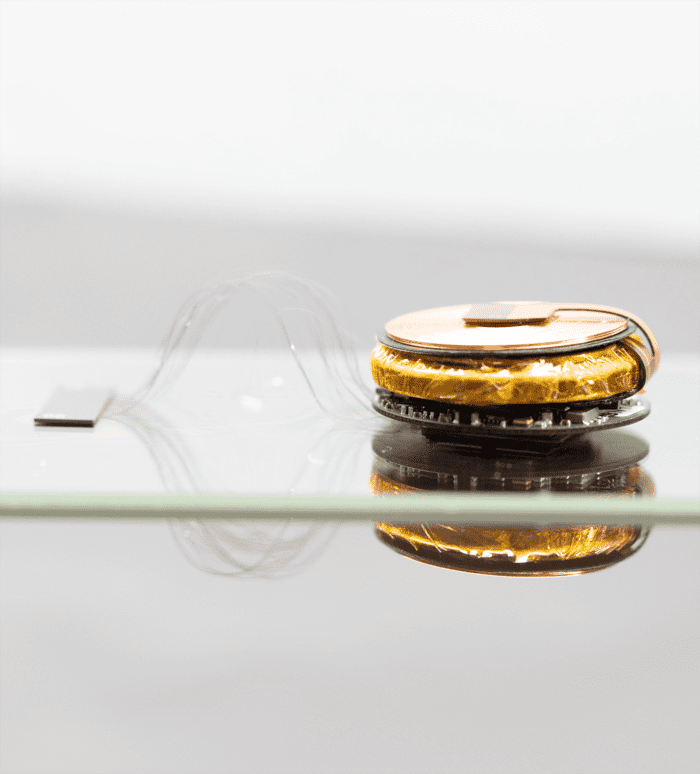

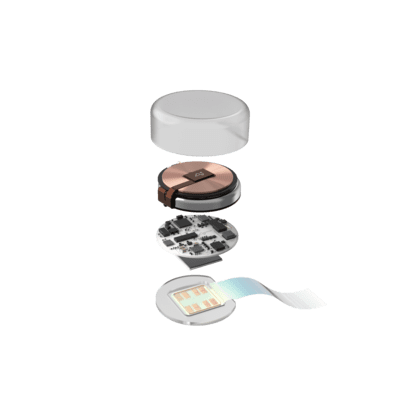

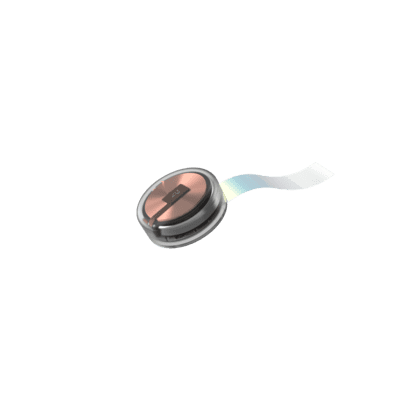

HERMETIC PACKAGING

The Link needs to be protected from the fluid and salts that bathe surrounding tissue.

Making a water-proof enclosure can be hard, but it’s very hard when that enclosure must

be constructed from biocompatible materials, replace the skull structurally, and allow

over a 1,000 electrical channels to pass through it. To meet this challenge, we are

developing innovative techniques to build and seal each major component of the package.

For example, by replacing the connection of multiple components with a process that

builds them as a single component, we can decrease device size and eliminate a potential

failure point.

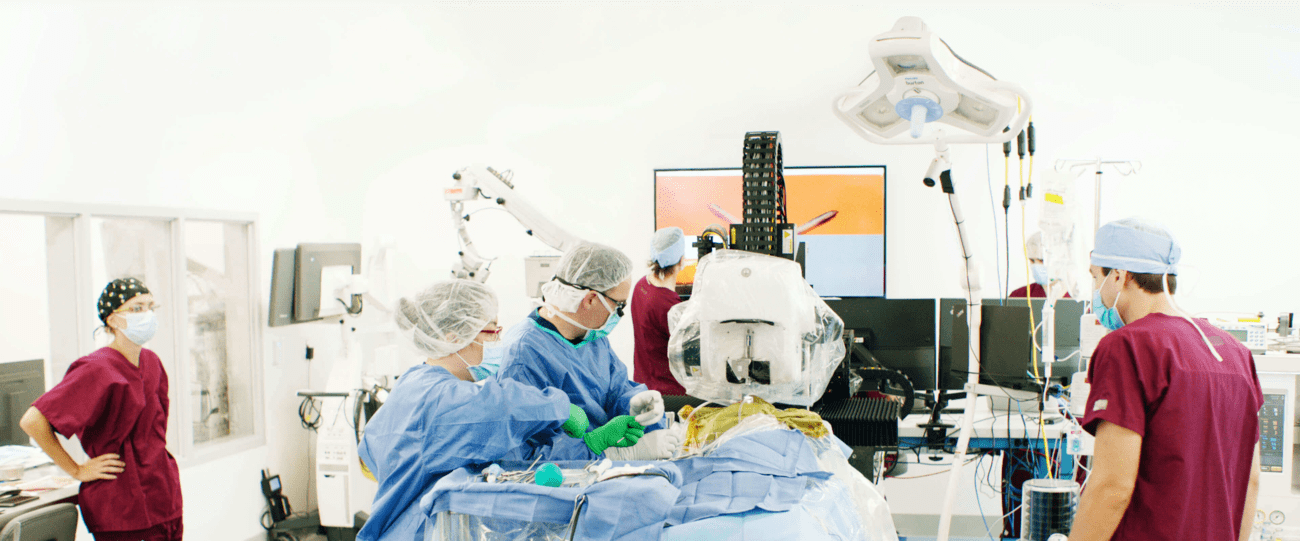

NEUROSURGERY

Our threads are too fine to be manipulated by hand and too flexible to go into the brain

on their own (imagine trying to sew a button with thread but no needle). Yet we need to

safely insert them with precision and efficiency. Our solution is based on a new kind of

surgical robot, whose initial prototype was developed at the University of California.

We are innovating on robot design, imaging systems, and software, to build a robot that

can precisely and efficiently insert many threads through a single 8 mm skull opening

while avoiding blood vessels on the surface of the brain.

NEURAL DECODING

Neural spikes contain a lot of information, but that information has to be decoded in

order to use it for controlling a computer. Academic labs have designed computer

algorithms controlling a virtual computer mouse from the activity of hundreds of

neurons. Our devices will be able to connect to over an order of magnitude more neurons.

We want to use the additional information for more precise and naturalistic control and

to include additional virtual devices such as a keyboard and game controller. To

accomplish this, we are building on recent advances in statistics and algorithm design.

One challenge is to design adaptive algorithms that maintain reliable and robust

performance while continuing to improve over time, including the addition of new

capabilities. Ultimately, we want these algorithms to run in real time on our low-power

devices.